For many parents and school administrators, the sight of a 3D printer whirring away in a classroom or library still seems like a novelty. It looks fun, futuristic, and maybe a little distracting. Students get to design and print small plastic trinkets, keychains, and figurines. But is it just an expensive toy, or is it a serious educational tool?

The answer is clear: when used correctly, the 3D printer is one of the most powerful and practical STEAM (Science, Technology, Engineering, Arts, and Math) tools available.

The value isn’t in the finished object; it’s in the process. It’s a desktop learning lab that bridges the gap between the digital and the physical, forcing students to learn the real-world skills that employers are desperate for. It’s not just teaching them about engineering; it’s teaching them how to think like an engineer.

Here’s how this one machine is building a new generation of innovators.

1. It Makes the Abstract Tangible

For many students, math and physics are abstract concepts. A discussion about “gear ratios” or “X, Y, Z coordinates” is just numbers on a whiteboard. A 3D printer forces them to apply those concepts in the physical world.

Suddenly, those “X, Y, Z coordinates” become a real, 3-dimensional object they can hold in their hand. A “gear ratio” isn’t a fraction; it’s a set of two gears they designed, printed, and can now physically snap together to see why one turns faster than the other.

This machine makes digital code and 3D models tangible, giving students a “click” of understanding that no textbook can. It’s the ultimate tool for “learning by doing.”

2. It Teaches the Single Most Valuable Engineering Skill: Iteration

In a traditional classroom, failure is final. You take a test, you get a grade, and you move on.

In 3D printing, failure is the beginning.

Here is a universal scenario: a student designs a custom phone stand. They print it. They put their phone on it, and it immediately snaps or falls over. This isn’t a “failure”; it’s data.

They are now forced to become a problem-solver. “Why did it break? The hinge was too thin.” “Why did it fall over? The center of gravity was wrong.”

They go back into the CAD software, thicken the hinge, widen the base, and print it again. This loop—design, print, test, fail, analyze, redesign, and reprint—is the single most important skill in modern engineering. It’s called iterative design, and it’s the exact process used by engineers at Tesla, NASA, and every other innovative company. It teaches resilience, critical thinking, and the value of “failing fast” to get to a better solution.

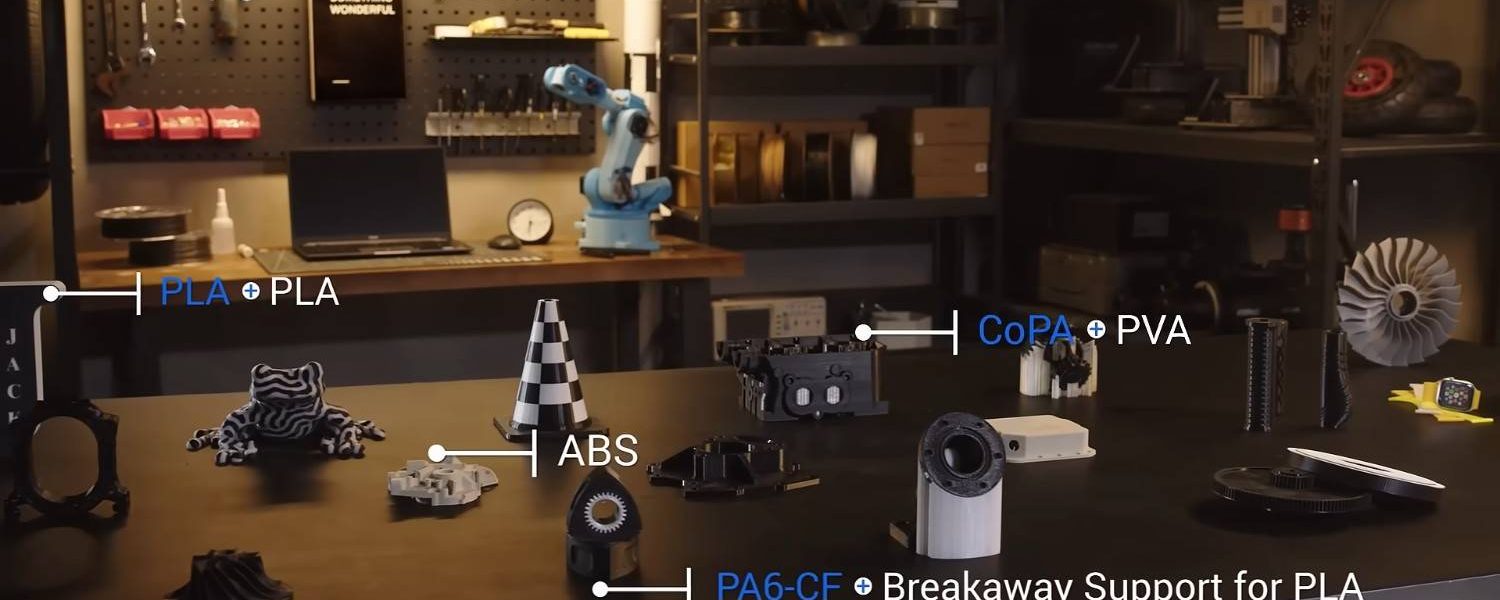

3. It’s a Hands-On Introduction to Material Science

The learning doesn’t stop with the design. The first print will likely be in a standard, easy-to-use material. For a classroom setting, teachers often start with safe and non-toxic 3D printer filament like PLA, which is plant-based and has no harmful fumes.

But what happens when that PLA part breaks, or a student needs a part that can bend? This opens a whole new line of inquiry.

“What if we print this in PETG instead? Will that be stronger?” “This phone case needs to be flexible. Should we use TPU?” “This part needs to be lighter but stiffer. What about a carbon-fiber composite?”

Suddenly, students are having real-world conversations about material properties, trade-offs, and selecting the right material for the job. They’re learning that PLA is brittle, PETG is tough, and TPU is flexible. This is hands-on material science, a core concept for any mechanical engineer or industrial designer.

Project-Based Learning That Solves Real Problems

The best way to integrate a 3D printer is to solve actual problems, not just print pre-made models from the internet.

- Simple Project: The Classroom Fix-It. Challenge students to find something in the classroom that’s broken or inefficient. A missing knob on a cabinet? A messy bundle of charging cables? A wobbly desk? They must measure the problem, design a part to fix it, and print a functional solution.

- Intermediate Project: Simple Machines. Instead of just reading about them, have students design, print, and assemble a working simple machine, like a block and tackle (pulley system) or a set of compound gears to demonstrate mechanical advantage.

- Advanced Project: Architectural Models. Have students design a “dream park” or a new layout for the school library in CAD software. They can then 3D print a scale model to present their idea, teaching them about architectural design and spatial awareness.

A Bridge from the Classroom to a Career

The 3D printer is far more than a toy. It’s a multi-disciplinary tool that rolls CAD design, engineering, material science, and problem-solving into a single, engaging activity.

Students who learn these iterative design and fabrication skills are not just “playing.” They are building the exact resume that high-tech companies, advanced manufacturing firms, and top-tier engineering programs are looking for. They’re learning to be the designers, engineers, and problem-solvers of tomorrow, one layer at a time.